PHYSICAL METALLURGY

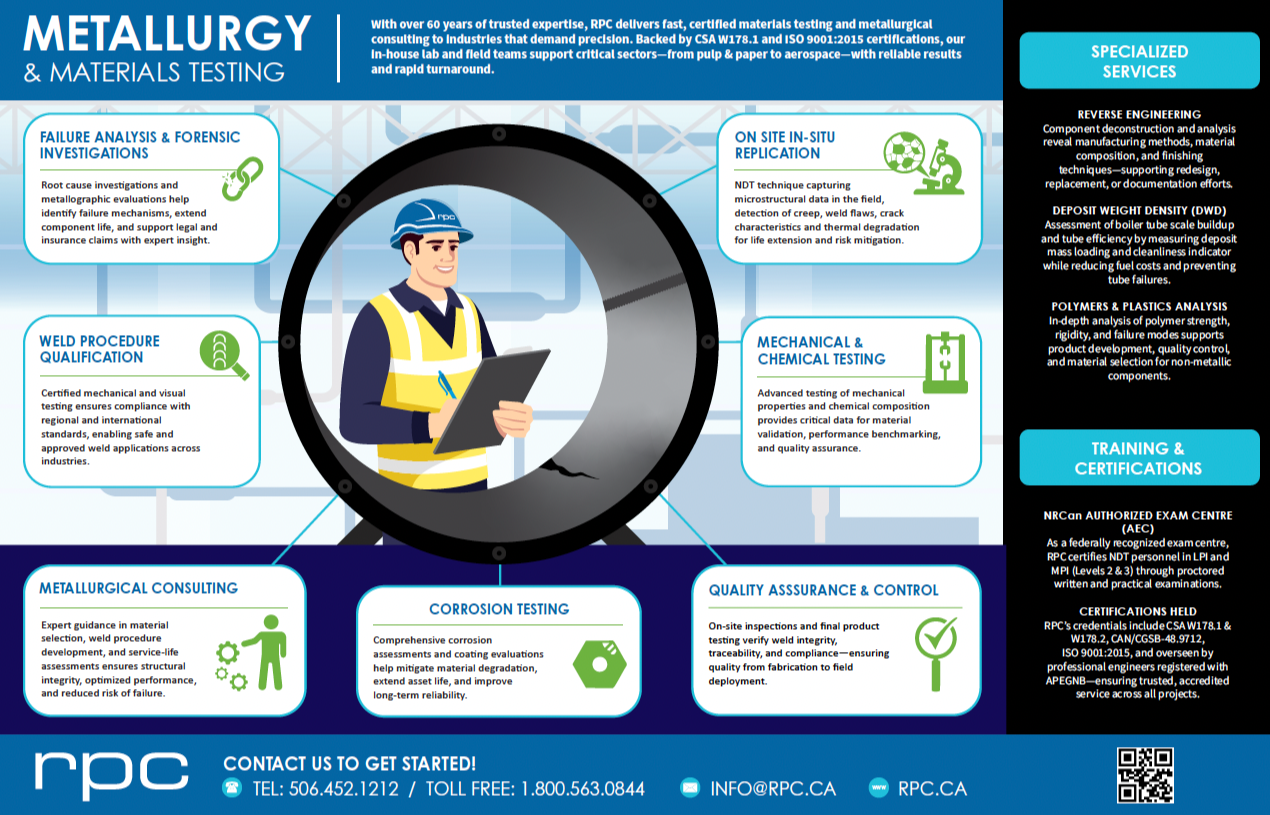

At RPC, we help industries overcome material-related issues quickly and effectively. Our experienced engineers and welding specialists supported by a fully equipped ISO 9001:2015 accredited materials testing facility, ensures rapid turnaround and exceptional service.

Failure Investigations

Expert metallurgical analysis to uncover the root cause of failures and safeguard your operations.

Failure investigations are considered when in-service or fabrication failures have major financial, safety, or legal implications, and for over six decades, RPC has been a trusted leader in metallurgical root-cause failure analysis and prevention strategies. Failures can occur in all types of environments and has led RPC to work diverse industries, including pulp and paper, nuclear, oil and gas, marine, aerospace, manufacturing, offshore operations, and many other miscellaneous facilities throughout the region.

OUR HIGHLY SKILLED TEAM SPECIALIZE IN:

Identifying root causes of in-service and fabrication failures

Preventing recurrence through proven recommendations

Enhancing reliability, safety, and quality assurance for your products and equipment

For legal and insurance professionals, RPC provides forensic metallurgical services to determine failure causes with precision and clarity.

Replications & Non-Destructive Testing (NDT)

Unlock precision and reliability with metallurgical in-situ field replication.

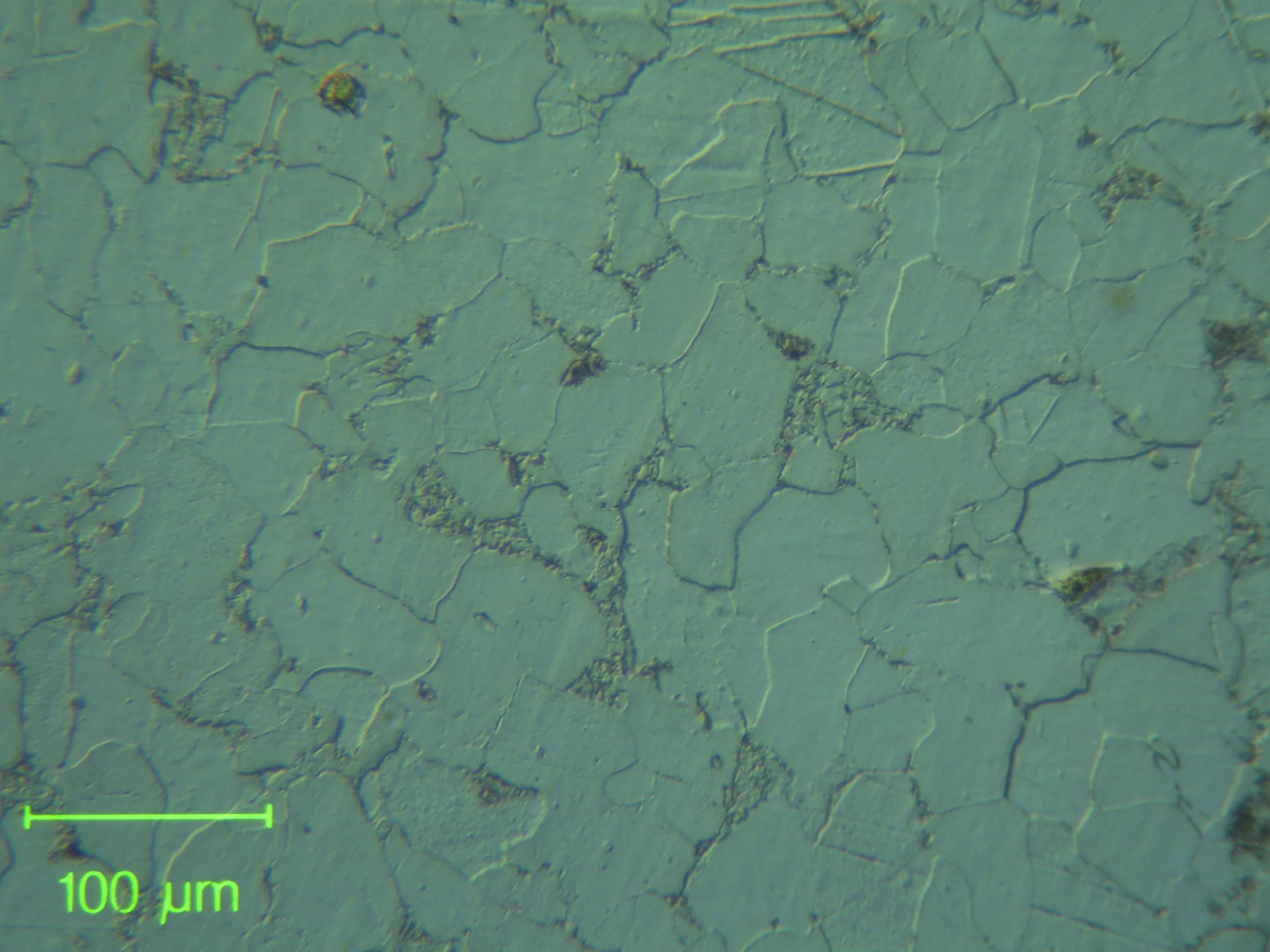

Ensure the integrity of your critical assets without costly downtime. Metallurgical in-situ field replication provides a fast, non-destructive solution for assessing material health directly on-site. By capturing accurate microstructural details from components in service that can be evaluated in the field for immediate results, or a more thorough detailed laboratory analysis at RPC’s facility. This technique enables proactive maintenance, compliance with industry standards, and extended equipment life—all without removing parts from operation.

WHY CHOOSE IN-SITU REPLICATION?

Cost-Effective: Avoid expensive shutdowns and unnecessary replacements.

Accurate & Reliable: High-resolution replicas for detailed metallurgical analysis.

Compliance Ready: Meet stringent inspection and safety requirements effortlessly.

Proactive Maintenance: Detect early signs of degradation before they become failures.

Stay ahead of material challenges—choose metallurgical in-situ field replication for smarter, safer, and more efficient asset management.

In addition to field replication work, RPC offers a full range of Non-Destructive Testing (NDT) inspections services, including videoscoping, strain gauging, and hardness testing. Testing can utilize its qualified personnel and perform on-site or in our laboratory using techniques such as liquid penetrant (LP), magnetic particle (MP), and ultrasonic examination (UT). Training and testing of NDT procedures are also provided at RPC. RPC has extensive experience in nuclear and fossil plants, pulp and paper mills, and oil and gas facilities.

Non-Destructive Testing Examination Centre

RPC is an approved NRCan examination centre for candidates seeking CGSB 48.9712 (ISO 9712) certification or recertification in non-destructive inspection methods. We offer both practical and written examinations for magnetic particle and liquid penetrant inspection methods, and written exams for all other NDT methods. Candidates must meet all NRCan training, prerequisites, and visual requirements before attempting any examination. A minimum of 24 hours’ notice is required to cancel scheduled exams.

Workshops are available upon request to review and practice magnetic particle and liquid penetrant inspection techniques.

SCHEDULE YOUR NDT EXAM TODAY:

ndtexam@rpc.ca

Mechanical & Corrosion Testing

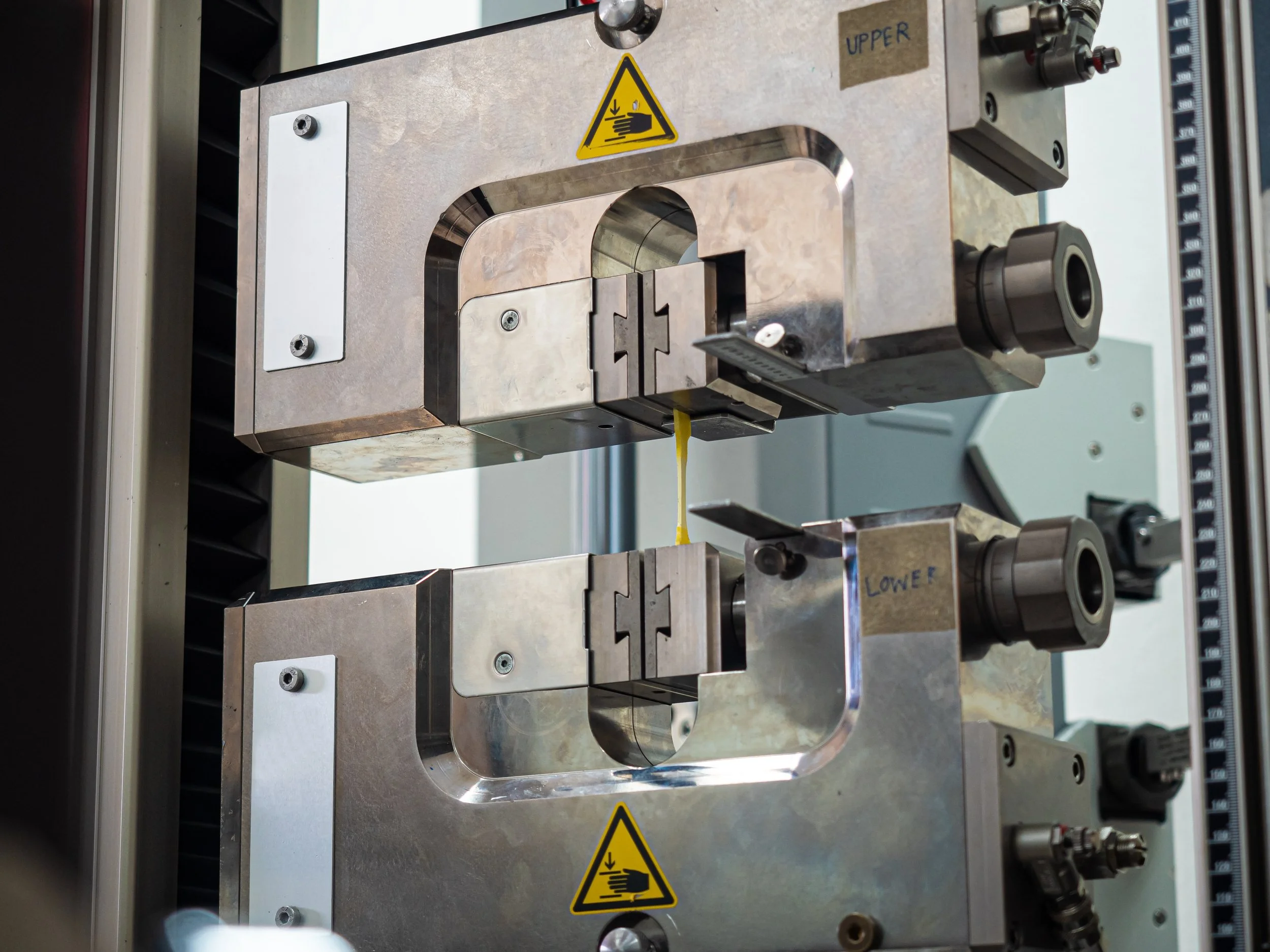

RPC offers comprehensive material testing services to evaluate corrosion resistance, mechanical strength, and physical properties of metals, composites, and alloys.

OUR ADVACNED METALLURGICAL LAB CAPABILITIES INCLUDE:

Mechanical Testing: Tensile, bend, nick-break, fatigue, hardness, and Charpy impact

Metallographic Assessment: Microstructure, grain size, case depth, and volume fraction

Corrosion Testing: Stress-corrosion and immersion methods

Material Identification: Chemical analysis, XRF, and SEM analysis

RPC can aid to verify materials meet standardized corrosion and material specifications including those from ASTM, NACE, ISO, ASME, AWS, API, and CSA, as well as client specified requirements—helping you maintain compliance, reliability, and performance.

Weld Procedure Qualification

Ensure your welded assemblies meet the specific requirements of North American and European standards with RPC’s corrosion and mechanical testing services. Our expertise covers major codes and specifications, including:

ASME Codes and Standards (Boiler and Pressure Vessel, Power Piping, Process Piping, Heat Transfer Components)

API Storage Tanks

AWS Weld Tests

CSA Welding Standards

Lloyd’s Register

Det Norske Veritas (DNV) Standards

Plus, client-specific requirements

With advanced testing capabilities and decades of experience, RPC helps you achieve compliance, reliability, and confidence in your welding procedures