MANUFACTURING & AUTOMATION

Mechanical & Electronic Engineering

RPC has a long history of providing engineering services to a wide selection of clients in diverse fields. Our team of mechanical and electrical engineers have the experience and know-how to provide a myriad of solutions to even the most challenging engineering problems.

SERVICES:

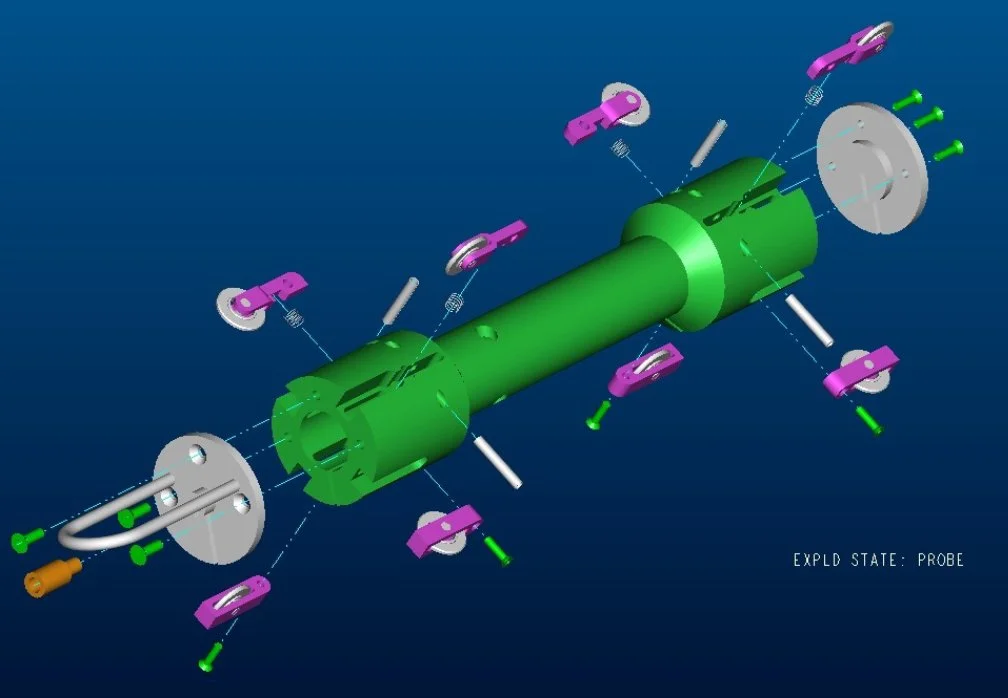

Mechanical Design (2D/3D)

Electrical Design

Electronic Design (PCB design and layout)

3D printing

Water-jet

CNC machining

Full machine shop capabilities

Heat treating

Welding

Custom Machining & Manufacturing

RPC works with manufacturers and entrepreneurs to help develop their ideas for innovative new products. Our modern machine shop is well suited for its specialized role in product development; equipped with a versatile range of tooling including laser cutter, coordinate measuring machine, CNC turning and milling centres, and a waterjet cutter. Heat treatment and welding facilities are also available.

RPC’s staff includes journeymen machinists, mechanical and electronic technologists and senior design engineers. Our staff have experience serving various industries including; food and beverage processing, pulp and paper, forestry and nuclear power.

SERVICES:

Manufacture first off prototypes

Short run machining

Manufacture hard to source parts

Over flow machining capacity

Laser cutting

Waterjet cutting

Plunge EDM cutting

Heat treating

Specialize in manufacturing for the nuclear industry and food processing

FACILITIES & EQUIPMENT:

Nakamura - Tome Superturn CNC Lathe

HAAS VF-2YT CNC 4 Axis Milling Machine

MAZAK CNC 4 Axis Milling Machine

Flow Mach 2b Waterjet Cutter

Mitutoyo CNC Coordinate Measuring Machine

Range of Conventional Mills and Lathes for Varying Applications

Surface Grinding Equipment

Heat Treating

Welding

Rapid New Product Development

Developing a new product takes considerable time and resources. If not managed correctly, the best idea can turn into a disaster. RPC can help clients with all phases of product development; from initial design to final prototype. Our design capabilities are outlined as follows:

INITIAL DESIGN:

RPC offers mechanical and electrical/electronic design services to help your idea become a reality. Our knowledgeable, multi-disciplined staff have access to various CAD tools to quickly and accurately produce a design based on a client’s requirements. We also have years of experience to help adjust the initial concept into something that can be manufactured reliably and at a reasonable price.

PROTOTYPING:

RPC offers various services to bring a final design to life; these include 3D printing, CNC machining, welding, and full machine shop capabilities. Using these services, RPC can create an almost exact replica of the final product, giving our clients the ability to visualize the final product for fit, finish and accuracy.

Digital Twinning & Simulation

The need for efficiency in today’s factories has never been greater with equipment and labor costs continuing to rise each year. Successful companies need to ensure that every aspect of their operation is being carefully considered and optimized. Digital twinning and factory simulation is an inexpensive, risk-free way to put your facility to the test, ensuring that you are meeting production goals and quality standards at the lowest possible cost.

WHY SIMULATE YOUR FACTORY?

Process optimization

Resource allocation

Predictive analysis

Error reduction

Reduced downtime

Waste reduction

Energy efficiency

Capital investment decisions

SERVICES:

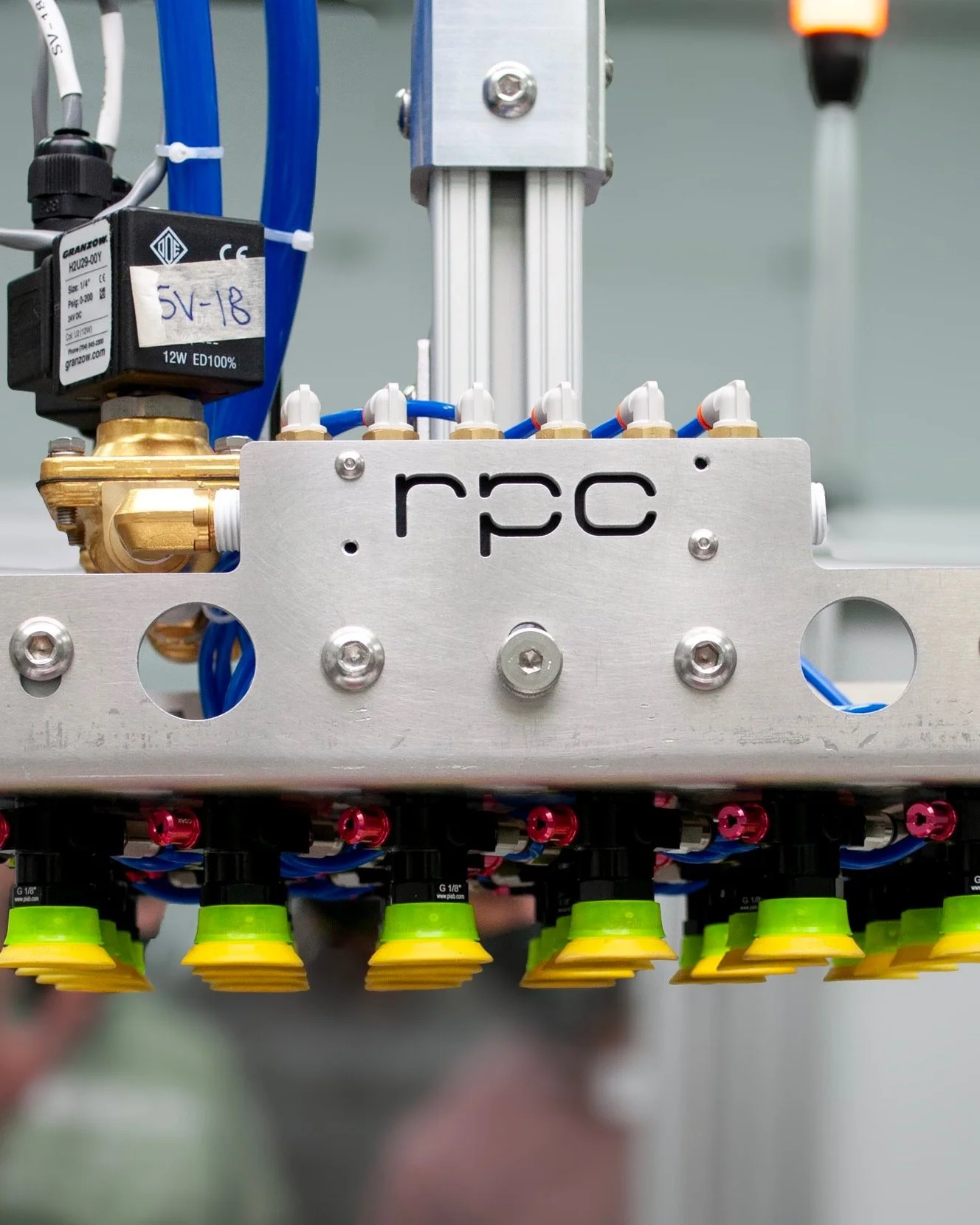

Automation, Machine Vision & Robotics

AUTOMATION:

The heart of most factories lies in automation. Automation can be used to implement a variety of tasks. Using items such as Programmable Logic Controllers (PLC), valves, cylinders and other actuators, RPC can add functionality to, or improve, your current process.

MACHINE VISION:

Machine Vision as in integral part of a manufacturers process for ensuring quality products that meet specifications. Machine vision can be used for:

measurement applications,

inspecting parts for flaws or defects,

proving location for pass reject stations or pick and place applications using robots,

part/label identification using QR codes, bar codes, readable characters.

RPC works with manufacturers to implement machine vision into their current operations to improve product quality and reliability.

ROBOTICS:

Robots are becoming a much more affordable resource for manufacturers. Robots can be used to improve the accuracy and speed of processes, as well as improve throughput on mundane tasks, freeing up your workers to deal with more technical operations. Some applications include:

pick and place applications

palletizing

RPC can work with clients to develop a robotic solution that will improve process speed and accuracy.

Engineering Services

Tel: 506.452.1212

Toll Free: 1.800.563.0844

info@rpc.ca