MINERAL PROCESSING

Advanced expertise and full‑scale capability for the mining sector.

RPC provides comprehensive mineral processing and metallurgical services to support mining projects at every stage—from early evaluation to full pilot‑scale testing. With deep experience across mineral dressing, hydrometallurgy, pyrometallurgy, bioleaching and environmental analysis, we help clients unlock value, improve recovery and advance technologies with confidence.

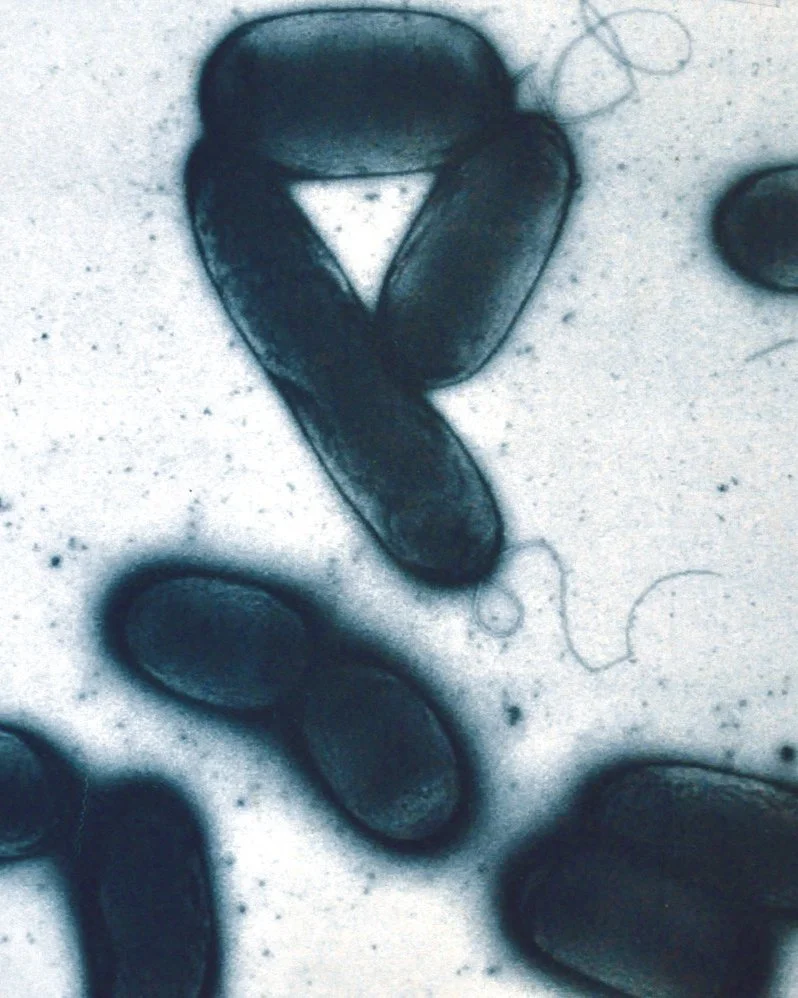

Our fully equipped pilot plant and multidisciplinary technical team comprised of chemists, metallurgists, mineralogists, physical metallurgists and chemical engineers, allow us to take on complex challenges across a wide range of ore types and processing scenarios. We specialize in assessing the potential to recover valuable metals using both established and emerging technologies, with recognized strength in bacterial leaching for low‑grade ores, concentrates and mine tailings.

MINERAL PROCESSING SERVICES:

Flotation

Gravity Separation

Bio‑hydrometallurgy (bioleaching, bioremediation, bioxoidation)

Hydrometallurgy

Pyrometallurgy

PILOT-SCALE ROASTING

RPC operates four fluidized bed roasters (2", 6", 8" and 12") in stainless steel and refractory configurations, providing the flexibility to meet diverse testing requirements. Each unit is supported by a full suite of gas‑cleaning and ancillary systems, including hot filters, cyclones, cold baghouses and condensers—enabling precise, reliable process evaluation.

ENVIRONMENTAL TESTING

Our environmental testing capabilities support responsible and compliant mining operations. We provide characterization and analysis of acid-generating rock, tailings, hazardous waste and asbestos, helping clients mitigate risk and meet regulatory obligations.

MINERAL PROCESSING CAPABILITIES

Our mineral processing services span crushing, sizing, grinding, gravity separation and flotation—allowing us to design and evaluate efficient flowsheets grounded in real‑world performance data.